BY BESTENIGAR KARA

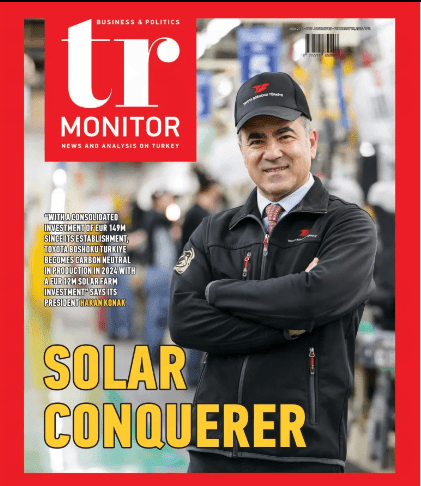

The Japanese carmaker Toyota Group’s automotive component manufacturer Toyota Boshoku Corporation’s Turkey operation Toyota Boshoku Turkiye (TBT) becomes carbon neutral in production this year with a EUR 12m Solar Farm investment. Thus, TBT will be the first subsidiary in Toyota Boshoku Corporation’s global operation to meet 100% of its energy with a facility outside the factory, according to Hakan Konak, President of TBT. “We’ll utilize the net energy metering (NEM) model in the Solar Farm project. We estimate its annual profit to be EUR 2.5m. Therefore, the project will amortize itself in four to five years,” Konak told in an exclusive interview with TR MONITOR.

TBT is the first and the most deep-rooted production base of Toyota Boshoku Corporation, which operates 91 production bases in 25 countries worldwide, in Europe. It takes a 2.4% share from its mother company’s global operation. Established in October 1997 in Sakarya, it has been manufacturing seats, door trim, seat covers, instrumental panel components, and air filters since 1998. “Based on our deep historical bond of 100 years, we became the first Japanese supplier to invest in Turkey when Toyota decided to invest in the country,” Konak noted. “The main factor of this decision was our faith in Toyota and our strong growth expectation for it,” he added.

In time, TBT’s product range has widened, and Toyota’s production bases in the UK, France, and South Africa have been added to Toyota Boshoku Turkiye’s customer portfolio.

TBT has made a consolidated investment of EUR 149m or TRY 4.8bn since its establishment in Turkey. While Toyota is the firm’s primary customer, it also manufactures for the German carmaker BMW. As for supply to Toyota, the firm produces for the Corolla and C-HR models.

TBT currently exports to six countries. France, South Africa, and Poland are the firm’s outstanding export markets. “More than half of the turnover of our manufacturing plant in Duzce consists of exports,” Konak said. TBT’s export volume hit EUR 33.3m last year. It expects a hike in exports with the inward processing certificate (D1), which it plans to receive in a few months.

AMONG TOYOTA’S JUST IN SEQUENCE SUPPLIERS

TBT operates three production plants in Sakarya and Duzce on over 100,000 square meters. It has an annual production capacity of 280,000 vehicle sets and has manufactured over 3.4 million units over the past 25 years. Its Duzce factory, incorporated by its 100% seat cover subsidiary TB Sewtech Turkey (TBSTR), produces 500,000 cover sets annually.

Moreover, TBT is among Toyota Manufacturing Europe’s ‘Just-intime’ and’ Just-in-sequence’ suppliers. “So, the manufacturing is reflected Toyota’s demand, including model and specification orders, on the production lines in real-time,” Konak noted.

The company, which continues to work to hit a 100% localization rate in production, has an almost 100% localization rate in molds and machinery, while its parts and materials have a 91% localization rate. It has reduced the overseas technical assistance requirement to zero in manufacturing processes since 2019 and started to support group companies in Europe and Africa Region.

TBT is also distinguished from its rivals in terms of awards. Among the most outstanding ones, the firm received the EFQM Turkey Excellence Award in 2020, 2022, and 2023 and the International Safety Award from the British Safety Council in 2023.

The company recently received the Top Employer 2024 Turkey certificate from the Top Employers Institute. While the certificate testifies that TBT’s Human Resources and Employee Management practices are at an exemplary level, only 29 firms in Turkey have this certificate.

TBT and TBSTR plants, which consume 14 GWh energy annually, will meet their power need from the EUR 12m Solar Farm, making TBT fully generate its power in 2024. The project positions TBT as the first subsidiary in Toyota Boshoku Corporation’s global operation to meet 100% of its energy with a facility outside the factory and as the first firm in its sector of operation in Turkey. TBT will use the NEM model in the project, making it carbon-neutral in production.

INSPIRES OTHERS IN DISABLED EMPLOYMENT

TBT has a three-shift operation for six days uninterruptedly. This operation model is the first and still the only one in Toyota Boshoku Corporation worldwide. It currently employs nearly 2,000 people. Women employment accounts for over 30% of total employment. “To raise women’s employment is an issue that we emphasize in our medium-term strategy and has been a hot topic in our agenda for three years. We clearly discriminate positively,” Konak said. From this perspective, women accounted for 83% of the firm’s total employment in 2022, while the figure is 100%, especially in the production site. The firm’s male operator employment has been zero since January 2022, excluding the office personnel. “We maintain the same policy this year and plan to raise the women’s employment on the office side as well.”

On the other hand, TBT kicked off a project at the end of 2021 towards the employment of gravely disabled people, of which the preparation process had continued for over a year. As part of it, TBT reorganized its production base from entrance to exit, including plants and production lines. TBT has employed ten walking disabled teammates since November 2022, including six colleagues at the Sakarya facility and four at the Duzce plant. The figure will continue to hike. The difference in this project is that these employees work directly at production lines and are included in the core operation under mass production conditions, while this feature is also the first in Toyota Boshoku Corporation’s global operations. Each disabled employee has two teammates in case of emergency and evacuation. “Our goal was to bring disabled people into the business and social life. We particularly focused on gravely disabled people to raise awareness and wanted to share that everyone can kick off such a project,” Konak said. The project has attracted intensive attention and inspired others. Municipalities, other institutions, and companies demanded that Toyota Boshoku Turkiye share this project and inform them.

BREAKS FRESH GROUND IN THE SECTOR

TBT fully utilized its capacity in 2022 and 2023 when it had no difficulties in employment or turnover and achieved profitability targets. “Our logistics and production efficiency work played a role in that. The positive results in environmental indicators such as waste minimization contributed to our profitability.”

Within the frame of sustainability, TBT approaches environmental, social, and governance (ESG) oriented investments under three main topics, including commissioning renewable energy resources, reducing energy consumption in daily works with continuous improvement, and making processes energy-efficient with engineering approaches and digitalization tools. It fully meets energy consumption from renewables to achieve the greenhouse gas emission targets. “This issue has been documented with the I-REC certificate with international validity,” Konak noted.

TBT’s Solar Farm project of EUR 12m focuses on becoming carbon neutral by using renewables. The project with the NEM model is also the first of its kind in TBT’s sector of operation in Turkey and will contribute to Toyota Boshoku Corporation and Toyota’s zero CO2 emission goals worldwide. The Solar Farm, with an installed power of 10 MWp, emerged through commitments and strategies to reduce carbon emissions concerning countries in terms of the Paris Agreement and EU Green Deal. TBT and TBSTR plants, which consume 14 GWh energy annually, will meet their power need from this project, making TBT fully generate its power this year. “I would like to convey my thanks to regulations and incentives for investments such as solar power plants,” Konak said. The TBT President, also a Board Member of the Automotive Suppliers Association of Turkey (TAYSAD), stated they are preparing a solar energy guide for TAYSAD.

Furthermore, TBT has started working to reduce emissions by calculating critical emission points such as personnel services, product and parts transport, and waste disposal, in addition to the production operations at the plants. As the first step, TBT transformed all trucks used in product deliveries to customers into electric vehicles. As part of the ISO 50001 Energy Management System and Green Procurement Policy, it will continue to prefer energy-efficient products in all products and equipment entering the factory and make its machinery and equipment energy efficient.

OPERATES WITH A PHILOSOPHY TO BE A GOOD CORPORATE CITIZEN

TBT, operating with a philosophy to be a good corporate citizen since its foundation, implements corporate social responsibility projects in education, environment, and sports. The company has implemented the “Rear Seat Belt Training” project for nine years. As part of the project, it trained 5,000 children. It also meets the needs of students and educational institutions, from primary schools to universities in Sakarya, with training and donations.

The firm, which carries out activities such as forestation and environmental cleaning to raise environmental protection awareness, established a Biological Wastewater Treatment Facility to reuse wastewater. The facility achieved a water quality for fish to live and feed.

TBT also works to protect and develop local values. It sponsors the Sakarya Women’s Volleyball Team to back social gender equality and support sports and sportswomen.

The company trained students of a vocational and technical school in Sakarya in occupational safety, quality, and efficiency, the basis of a production site, as part of the Foundations of the Production Site project, which kicked off in 2023. Moreover, it plans to start a pilot project in February to reveal the efficiency dimension of the production lesson and include it in the curriculum.

TBT has been manufacturing environmentally friendly products such as teddy bears and pencil boxes from waste leather and fabrics since 2017. With the TBear application, inspired by the first two letters of Toyota Boshoku Turkey, employees develop their sewing skills while the firm instills the importance of waste reduction.

The firm donates products to local charities and schools for children above three years old.

TBT carries out comprehensive activities with employee participation, from blood and bone marrow to book and toy donation and cleaning activities.